I found a good website which broke down the wide variety of technologies that are used within the industry: https://www.prepressure.com/printing/processes

The main industrial printing processes are:

- Offset lithography

- Flexography

- Digital printing: inkjet & xerography

- Gravure

- Screen printing

Offset

In offset lithography a printing plate, which is most often made from aluminium, contains an image of the content that needs to be printed. When the plate is inked, only this image part holds ink. That inked image is subsequently transferred (or offset) from the plate to a rubber blanket and then to the printing surface. The process can be used to print on paper, cardboard, plastic or other materials, but these have to have a flat surface.

Below is a picture of a 4 colour sheetfed printing press, similar to that at the Precision print warehouse we visited. At the far end is the intake where individual sheets of paper are automatically fed into the press. The 4 towers or printing units each print one colour, typically black get printed first, followed by cyan, magenta and yellow. The stack of printed sheets is visible on the front of the machine, underneath the press console & monitor which the press operator uses to control the press.

For higher volume work offset presses use rolls of paper. The picture below shows such a much larger web press. It is so fast that the printed paper needs to be force dried. The black unit at the end of the press is an oven.

Offset is nowadays the most widely used printing technique for an extensive range of products such as books, newspapers, stationery, corrugated board, posters, etc. It is the process I would be using if I did want to get a publication/editorial copy mass produced for a client and it only gets cheaper the bigger the batch you need.

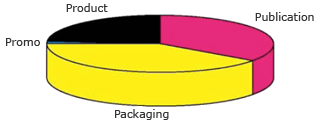

There is a trend that printing promotional material is gradually migrating to digital printing while some packaging printing is moving to flexo.

There is a trend that printing promotional material is gradually migrating to digital printing while some packaging printing is moving to flexo.Flexo

In flexography the content that needs to be printed is on a relief of a printing plate, which is made from rubber. This plate is inked and that inked image is subsequently transferred to the printing surface. The process can be used to print on paper as well as plastics, metals, cellophane and other materials. Flexo is mainly used for packaging and labels and to a lesser extent also for newspapers so is not appropriate or feasible for me at university.

Digital printing

Digital printing can be done in various ways. Two technologies dominate the industry:

- Inkjet – In an inkjet printer the image that needs to be printed is created by small droplets of ink that are propelled from the nozzles of one or more print heads. Inkjet devices can print on a wide range of substrates such as paper, plastic, canvas or even doors and floor tiles. Inkjet printing is used a lot for poster and signage design. It is also economical for short run publications such as photo books or small runs of books which is making it the process which is realistically most appropriate, but also available and feasible for me at uni.

- Xerography – In xerographic printers, such as laser printers, the image that needs to be printed is formed by selectively applying a charge to a metal cylinder called a drum. The electrical charge is used to attract toner particles. These particles are transferred to the media that is being printed on. To make sure the toner is fixed properly, the substrate passes through a fuser that melts the toner into the medium. Laser printers are not only used in offices but also for small run printing of books, brochures and other types of document. These printers are also used for transactional printing (bills, bank documents, etc) and direct mail.

Digital printing is increasingly utilised for print jobs that were previously printing using offset, flexo or screen printing.

Digital printing is increasingly utilised for print jobs that were previously printing using offset, flexo or screen printing.- In short run small format (A3 size) printing, digital is taking over from offset for both colour and B&W printing. Quick printers and copy shops print digitally on presses from vendors like Xerox, HP, Canon, and Konica Minolta.

- Labels are also increasingly being printed digitally.

- Billboard and point-of-sale or point-of-purchase jobs are being done by wide-format inkjet devices.

Gravure

Also known as rotogravure, this is a technique in which an image is engraved into a printing cylinder. That cylinder is inked and this ink subsequently transfers to the paper. Gravure is used for high volume work such as newspapers, magazines, and packaging, so isn't a process that is easily available to me or suitable for a photobook publication in comparison to the advantages that the other processes offer.

Gravure is gradually losing market share to offset for publication printing and to flexo for packaging applications.

Gravure is gradually losing market share to offset for publication printing and to flexo for packaging applications.Screen printing

The last technique I will discuss is one I am now experienced in and could decide to apply this technique to sections of my publication if justified. It relies on a screen, which is a woven piece of fabric. Certain areas of this mesh are coated with a non-permeable material. In the remaining open spaces ink can be pushed through the mesh onto a substrate. The advantage of screen printing is that the surface of the recipient does not have to be flat and that the ink can adhere to a wide range of materials, such as paper, textiles, glass, ceramics, wood, and metal. With the ease, precision and repeatability that other print methods such as digital and offset can offer graphic designers the print age is slowing down however you can't replicate the finish a perfectly screen-printed piece of design has.

Distribution

When it comes to actually distributing a publication, or more specifically a coffee table photo-book, as they are beautifully bound hard-back covers with high-end printing within they will be sold within Book stores or online in batches dependant on its popularity/demand. They can be quite expensive dependant on the content and its rarity, so designers tend to charge even more for small-batches of 100 to make it more of a collectors item. This is something I could look into doing, but because I am only a student I wouldn't breach £20, dependant on the overall pricing of production which I will be able to work out once my designs have been confirmed and tested.

For coverage I would promote my publication online on social networks aimed at online groups of pretty much all ages of travellers and the design community. Also by just leaving a couple of copies in Colours May Vary or Village book store I can see how it would weigh up against actual industry released for sale publications.

No comments:

Post a Comment